Resumen

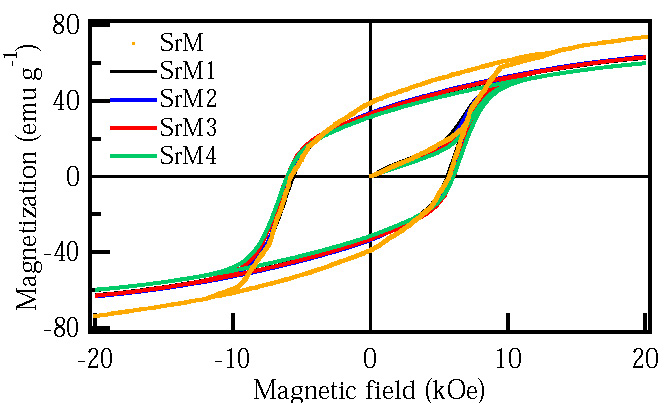

In this work, neodymium (Nd3+) doped strontium hexaferrite was obtained using the sol–gel based Pechini method. The cation distribution was modified by doping with different amounts of Nd3+ ions when 0.0 ? x ? 0.4 according to the chemical expression Sr1-xNdxFe12O19 the powders were sintered at 1100 °C for 1 h. The influence of the neodymium was analyzed, and the magnetic and structural properties have been associated with the fabrication method. The crystalline phases, structure, and particle morphology of the samples were determined by X-ray diffraction, scanning electron microscopy, and transmission electron microscopy. In addition, the magnetic properties were measured at room temperature using a vibrating sample magnetometer with an applied field of up to 20 kOe. Moreover, magnetization and coercivity values are influenced by the neodymium content. The results showed that the Pechini sol-gel method allows a limited solubility of the Nd3+ ions on the hexaferrite structure.

Citas

.[1]. R.C. Pullar, Prog. Mater. Sci. 57, 1191 (2012).

https://doi.org/10.1016/j.pmatsci.2012.04.001

.[2]. W. Onreabroy, K. Papato, G. Rujijanagul, K. Pengpat, T. Tunkasiri, Ceram. Int. 38, 415 (2012).

https://doi.org/10.1016/j.ceramint.2011.05.023

.[3]. L. Klein, M. Aparicio, A. Jitianu, Handbook of sol-gel science and technology: Processing, characterization and applications, 2nd Ed. (Springer, 2018).

https://doi.org/10.1007/978-3-319-32101-1

.[4]. S. Rana, A. Gallo, R. Srivastava, R. Misra, Acta Biomater. 3, 233 (2007).

https://doi.org/10.1016/j.actbio.2006.10.006

.[5]. M.A. Urbano, S.A. Palomares, I. Betancourt, T.J. Pérez, F. Ruiz, Appl Phys. A 125, 1 (2019).

https://doi.org/10.1007/s00339-019-3004-z

.[6]. J.R. Lui, R.R. Hong, W.G. Feng, D. Badami, Y.Q. Wang, Powder Technol. 262, 142 (2014).

https://doi.org/10.1016/j.powtec.2014.04.076

.[7]. S.M. Masoudpanah, A. Seyyed, J. Magn. Magn. Mater. 342, 128 (2013).

https://doi.org/10.1016/j.jmmm.2013.04.070

.[8]. K. Kim, K. Jeon, K.W. Moon, M.K. Kang, J. Kim, IEEE Trans. Magn. 52, 1 (2016).

https://doi.org/10.1109/TMAG.2016.2531119

.[9]. R.L. Palomino, A.M. Bolarín, F.N. Tenorio, F. Sánchez, C.A. Cortés, S. Ammar, Ultrason. Sonochem. 29, 470 (2016).

https://doi.org/10.1016/j.ultsonch.2015.10.023

.[10]. J. Malick, N. Virginie, B. Julien, L.B. Jean, J. Alloys Compd. 496, 306 (2010).

https://doi.org/10.1016/j.jallcom.2010.02.002

.[11]. G.H. An, T.Y. Hwang, Y.H. Choa, S. Kyoosik, J. Electron. Mater. 43, 3574 (2014).

https://doi.org/10.1007/s11664-014-3228-9

.[12]. S.E. Shirsath, S.S. Jadhav, M.L. Mane, S. Li, Ferrites obtained by sol-gel method. In: Handbook of sol-gel science and technology, Eds. L. Klein, M. Aparicio, A. Jitianu (Springer, 2016) pp. 1-41.

https://doi.org/10.1007/978-3-319-19454-7_125-1

.[13]. B. Hamid, B. Want, J. Appl. Phys. 122, 1 (2016).

https://doi.org/10.1007/s00339-016-9687-5

.[14]. J. Luo, Mater. Lett. 80, 162 (2012).

https://doi.org/10.1016/j.matlet.2012.04.107

.[15]. H. Khanmohammadi, E.S. Seyyed, Funct. Mater. Lett. 4, 283 (2011).

https://doi.org/10.1142/S1793604711001981

.[16]. M. Effendi, E. Solihah, C. Kurniawan, W.T. Cahyanto, W. Widanarto, Key Eng. Mater. 855, 255 (2020).

https://doi.org/10.4028/www.scientific.net/KEM.855.255

.[17]. M.A. Almessiere, Y. Slimani, A. Baykal, Ceram. Int. 45, 963 (2019).

https://doi.org/10.1016/j.ceramint.2018.09.272

.[18]. T. Pérez, I. Betancourt, S.P. Sánchez, M.M. García, J.M. Aquino, A.L. Guerrero, J. Supercond. Nov. Magn. 24, 2325 (2011).

https://doi.org/10.1007/s10948-011-1193-6

.[19]. K. Takeyuki, N. Tatsuya, Y. Tohru, N. Makoto, F. Tatsuo, T. Jun, I. Yasunori, J. Magn. Magn. Mater. 322, 2381 (2010).

https://doi.org/10.1016/j.jmmm.2010.02.041

.[20]. P. Kumar, A. Gaur, Superlattices Microstruct. 120, 305 (2018).

https://doi.org/10.1016/j.spmi.2018.05.042

.[21]. M. Ghimire, D. Kunwar, J. Dahal, D. Neupane, S. Yoon, S. Mishra, Mater. Sci. Appl. 11, 474 (2020).

https://doi.org/10.4236/msa.2020.117033

.[22]. Y. Yang, D. Huang, F. Wang, J. Shao, Chin. J. Phys. 57, 250 (2019).

https://doi.org/10.1016/j.cjph.2018.11.012

.[23]. M. Elansary, M. Belaiche, C. Ahmani, E. Iffer, I. Bsoul, RSC Adv. 10, 25239 (2020).

https://doi.org/10.1039/D0RA04722H

.[24]. M. Changye, M. Zhijun, L. Jun, R. Mingjun, Z. Xin, P. Zhiwei, J. Rare Earths 39, 1415 (2021).

https://doi.org/10.1016/j.jre.2020.08.011

.[25]. A. Hashhash, A. Hassen, W.S. Baleidy, H.S. Refai, J. Alloys Compd. 873, 1 (2021).

https://doi.org/10.1016/j.jallcom.2021.159812

.[26]. C. Lei, S. Tang, Y. Du, Ceram. Int. 42, 15511 (2016).

https://doi.org/10.1016/j.ceramint.2016.06.204

.[27]. A.Z. Simoes, C. Quinelato, A. Ries, B.D. Stojanovic, E. Longo, J.A. Varela, Mater. Chem. Phys. 98, 481 (2006).

https://doi.org/10.1016/j.matchemphys.2005.09.070

.[28]. M. Ferrari, L. Lutterotti, J. Appl. Phys. 76, 7246 (1994).

https://doi.org/10.1063/1.358006

.[29]. X. Obradors, X. Solans, A. Collomb, D. Samaras, J. Rodríguez, M. Pernet, M. Font, J. Solid State Chem. 72, 218 (1988).

https://doi.org/10.1016/0022-4596(88)90025-4

.[30]. A. Thakur, R.R. Singh, P.B. Barman, Mater. Chem. Phys. 141, 562 (2013).

http://dx.doi.org/10.1016/j.matchemphys.2013.05.063

.[31]. Q. Fang, H. Cheng, J. Huang, R. Wang, R. Li, Y. Jiao, J. Magn. Magn. Mater. 294, 281 (2005).

https://doi.org/10.1016/j.jmmm.2004.12.024

.[32]. S. Cotton, Electronic and magnetic properties of the lanthanides. In: Lanthanide and actinide chemistry, Ed. S. Cotton (Wiley, 2016) pp. 61-87.

https://doi.org/10.1002/0470010088

.[33]. B. Hamid, B. Want, Appl. Phys. A 122, 148 (2016).

https://doi.org/10.1007/s00339-016-9687-5

.[34]. P. Kumar, S.K. Sharma, M. Knobel, J. Chand, M. Singh, J. Electroceramics 27, 51 (2011).

https://doi.org/10.1007/s10832-011-9649-4

.[35]. N. Rezlescu, C. Doroftei, E. Rezlescu, P.D. Popa, J. Alloys Compd. 451, 492 (2008).

https://doi.org/10.1016/j.jallcom.2007.04.102

.[36]. M.J. Iqbal, S. Farooq, Mater. Res. Bull. 46, 662 (2011).

https://doi.org/10.1016/j.materresbull.2011.01.025

.[37]. M.N. Ashiq, M.J. Iqbal, I.H. Gul, J. Alloys Compd. 487, 341 (2009).

https://doi.org/10.1016/j.jallcom.2009.07.140

.[38]. A. Thakur, R.R. Singh, P.B. Barman, Mater. Chem. Phys. 141, 562 (2013).

http://dx.doi.org/10.1016/j.matchemphys.2013.05.063

.[39]. E.C. Stoner, E.P. Wohlfarth, Philos. Trans. Roy. Soc. 240, 599 (1948).

https://doi.org/10.1098/rsta.1948.0007

.[40]. B.H. Bhat, B. Want, Appl. Phys. 122, 1 (2016).

https://doi.org/10.1007/s00339-016-9687-5

.[41]. M. Naeem, A. Sami, S. Farooq, M. Najam, S. Rehman, J. Magn. Magn. 444, 426 (2017).

https://doi.org/10.1016/j.jmmm.2017.08.065

.[42]. M.M. Rashad, I.A. Ibarhim, J. Supercond. Nov. Magn. 26, 1639 (2013).

https://doi.org/10.1007/s10948-012-1871-z

.[43]. G. Nabiyouni, A. Ahmadi, D. Ghanbari, H. Halakouie, J. Mater. Sci. Mater. 27, 1 (2016).

https://doi.org/10.1007/s10854-016-4296-9

.[44]. J. Lee, E.J. Lee, T.Y. Hwang, J. Kim, Y.H. Choa, Sci. Rep. 10, 1 (2020).

https://doi.org/10.1038/s41598-020-72608-0

.[45]. Q. Li, J. Song, M.S. Múzquiz, F. Besenbacher, M. Christensen, M. Dong, Sci. Rep. 6, 1 (2016).

Esta obra está bajo una licencia internacional Creative Commons Atribución 4.0.

Derechos de autor 2022 Array