Mechanical properties and Keratinocytes cellular evaluation of Polycaprolactone/Collagen/Elastin Electrospun Fiber Scaffolds

DOI:

https://doi.org/10.47566/2022_syv35_1-221001Keywords:

Biopolymer, electrospun, keratinocytes, fibers, tissue engineeringAbstract

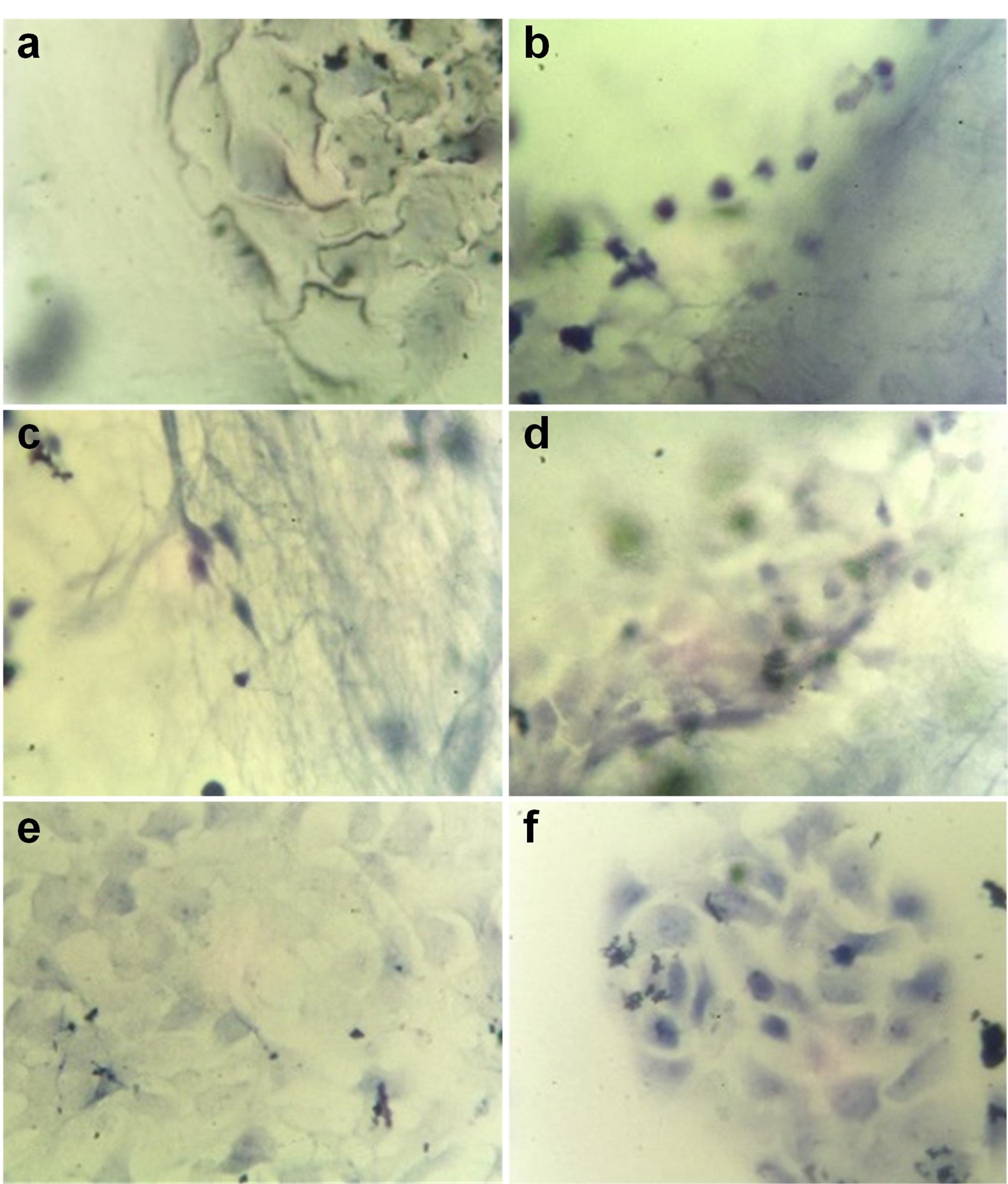

Bioinspired membranes as extracellular matrices are desired for skin regeneration. Herein, we fabricate four systems of fibrillar membranes composed of polycaprolactone (PCL), aminolyzed PCL, denatured collagen type I (C), and the blend of collagen hydrolysate types I and III (bC) or elastin (E), fabricated by the electrospinning process. The superficial features by SEM and optical profilometry, mechanical properties by puncture strength assays, and biological evaluation with a human keratinocyte cell line (HaCaT) for one day of aPCL6bCE (aPCL/collagen hydrolysate type I and III/Elastin), aPCL6CE (aPCL/denaturated Col I/elastin), aPCL6bC (aPCL/collagen hydrolysate type I and III), and PCL6bCE (PCL/collagen hydrolysate type I and III/Elastin) membranes are described. The aPCL6bCE and aPCL6CE fibers resulted in better structural properties for culturing cells, while aPCL6bC and PCL6bCE membranes have shown lower viability for keratinocytes, probably due to their different chemical surface and nanotopography. The roughness of these materials varied from 4.53 to 114.4 µm, depending on their diameter values. Puncture strength results were not significantly different within 2.25–2.66 MPa. Our results suggest that aPCL6bCE and aPCL6CE fibers have potential applications in skin tissue engineering, where the synergy among aminolyzed PCL and E seems to be a prerequisite to developing such activity.

References

.[1]. F. Groeber, M. Holeiter, M. Hampel, S. Hinderera, K. Schenke-Laylandac, Adv. Drug Deliv. Rev. 63, 352 (2011).

https://doi.org/10.1016/j.addr.2011.01.005

.[2]. J.K. Kular, S. Basu, R.I. Sharma, J. Tissue Eng. 5, 1 (2014).

https://doi.org/10.1177/2041731414557112

.[3]. S. MacNeil, Nature 445, 874 (2007).

https://doi.org/10.1038/nature05664

.[4]. A.D. Metcalfe, M.W.J. Ferguson, J. R. Soc. Interface 4, 413 (2007).

https://doi.org/10.1098/rsif.2006.0179

.[5]. Q. Chen, S. Liang, G.A. Thouas, Prog. Polym. Sci. 38, 584 (2013).

https://doi.org/10.1016/j.progpolymsci.2012.05.003

.[6]. R. Parenteau-Bareil, R. Gauvin, F. Berthod, Materials 3, 1863 (2010).

https://doi.org/10.3390/ma3031863

.[7]. C. Chaubaroux, E. Vrana, C. Debry, P. Schaaf, B. Senger, J.C. Voegel, Y. Haikel, C. Ringwald, J. Hemmerlé, P. Lavalle, F. Boulmedais, Biomacromolecules 13, 2128 (2012).

https://doi.org/10.1021/bm300529a

.[8]. D. Grafahrend, K.H. Heffels, M. Möller, D. Klee, J. Groll, Macromol. Biosci. 10, 1022 (2010).

https://doi.org/10.1007/s00441-011-1237-z

.[9]. J.L. García, A. Asadinezhad, J. Pacherník, M. Lehocký, I. Junkar, P. Humpolí?ek, P. Sáha, P. Valášek, Molecules 15, 2845 (2010).

https://doi.org/10.3390/molecules15042845

.[10]. B.S. Kim, I.K. Park, T. Hoshiba, H.L. Jiang, Y.J. Choi, T. Akaike, C.S. Cho, Prog. Polym. Sci. 36, 238 (2011).

https://doi.org/10.1016/j.progpolymsci.2010.10.001

.[11]. S.A. Sell, P.S. Wolfe, K. Garg, J.M. McCool, I.A. Rodriguez, G.L. Bowlin, Polymers 2, 522 (2010).

https://doi.org/https://doi.org/10.3390/polym2040522

.[12]. M.A. Woodruff, D.W. Hutmacher, Prog. Polym. Sci. 35, 1217 (2010).

https://doi.org/10.3390/polym2040522

.[13]. Y.E. Aguirre-Chagala, V. Altuzar, E. León-Sarabia, J.C. Tinoco-Magaña, J.M. Yañez-Limón, C. Mendoza-Barrera, Mater. Sci. Eng. C 76, 897 (2017).

https://doi.org/10.1016/j.msec.2017.03.118

.[14]. A.L. Butcher, G.S. Offeddu, M.L. Oyen, Trends Biotechnol. 32, 564 (2014).

https://doi.org/10.1016/j.tibtech.2014.09.001

.[15]. B. Dhandayuthapani, Y. Yoshida, T. Maekawa, D.S. Kumar, Int. J. Polym. Sci. 2011, 1 (2011).

https://doi.org/10.1155/2011/290602

.[16]. Q.L. Loh, C. Choong, Tissue Eng. Part B Rev. 19, 485 (2013).

https://doi.org/10.1089/ten.teb.2012.0437

.[17]. J.R. Venugopal, R. Sridhar, R. Rajeswari, M. Shayanti, B. Ramalingam, S. Subramanian, R. Seeram, Wound Repair Regen. 21, 1 (2013).

https://doi.org/10.1111/j.1524-475x.2012.00861.x

.[18]. M.R. Matus-Muñoz, R. Ruiz-Ramos, V. Altuzar, H.I. Beltrán, M.A. Palomino-Ovando, C. Mendoza-Barrera, Int. J. Polym. Mater. Polym. Biomater. 2021, 1 (2021).

https://doi.org/10.1080/00914037.2021.1895157

.[19]. F.H. Silver, J.W. Freeman, D. DeVore, Skin Res. Technol. 7, 18 (2001).

https://doi.org/10.1034/j.1600-0846.2001.007001018.x

.[20]. R. Ohtsuki, T. Sakamaki, S. Tominaga, Opt. Rev. 20, 94 (2013).

https://doi.org/10.1007/s10043-013-0014-5

.[21]. A. Kalra, A. Lowe, A.M. Al-Jumaily, J. Material. Sci. Eng. 5, 254 (2016).

.[22]. K. Khaothong, In: C.T. Lim, J.C.H. Goh (eds) 6th World Congress of Biomechanics (WCB 2010), IFMBE Proceedings 31, (Springer, Berlin) pp. 1467-1470.

https://doi.org/10.1007/978-3-642-14515-5_374

.[23]. Y. Zheng, A.F.T. Mak, IEEE Eng. Med. Biol. Soc. 7, 257 (1999).

https://doi.org/10.1109/86.788463.

.[24]. P. Sangsanoh, O. Suwantong, A. Neamnark, P. Cheepsunthorn, P. Pavasant, P. Supaphol, Eur. Polym. J. 46, 428(2010).

https://doi.org/10.1016/j.eurpolymj.2009.10.029

.[25]. T. Zhou, N. Wang, Y. Xue, T. Ding, X. Liu, X. Moc, J. Suna, Colloids Surf. B Biointerfaces 143, 415 (2016).

https://doi.org/10.1016/j.colsurfb.2016.03.052

.[26]. M. Kempf, Y. Miyamura, P.Y. Liu, A.C.H. Chen, H. Nakamura, H. Shimizu, Y. Tabata, R.M. Kimble, J.R. McMillan, Biomaterials 32, 4782 (2011).

https://doi.org/10.1007/s40204-014-0030-y

.[27]. K.S. Rho, L. Jeong, G. Lee, B.M. Seo, Y.J. Park, S.D.Hong, S. Roh, J.J. Cho, W.H. Park, B.M. Min, Biomaterials 27, 1452 (2006).

https://doi.org/10.1016/j.biomaterials.2005.08.004

.[28]. J. Pelipenko, P. Kocbek, J. Kristl, Eur. J. Pharm. Sci. 66, 29 (2015).

https://doi.org/10.1016/j.ejps.2014.09.022

.[29]. J. Pelipenko, P. Kocbek, B. Govedarica, R. Rošic, S.Baumgartner, J. Kristl, Eur. J. Pharm. Biopharm. 84, 401 (2013).

https://doi.org/10.1016/j.ejpb.2012.09.009

.[30]. P. Bhattacharjee, D. Naskar, H.W. Kim, T.K. Maiti, D. Bhattacharya, S.C. Kundu, Eur. Polym. J. 71, 490 (2015).

https://doi.org/10.1016/j.actbio.2017.09.027

.[31]. N.M. Alves, I. Pashkuleva, R.L. Reis, J.F. Mano, Small 6, 2208 (2010).

Downloads

Published

Issue

Section

License

Copyright (c) 2022 The authors; licensee SMCTSM, Mexico.

This work is licensed under a Creative Commons Attribution 4.0 International License.

©2025 by the authors; licensee SMCTSM, Mexico. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).