Structural properties of ceramic powders of CeO2:Eu2O3

DOI:

https://doi.org/10.47566/2025_syv38_1-250601Keywords:

sol-gel, CeO2, Eu2O3, powdersAbstract

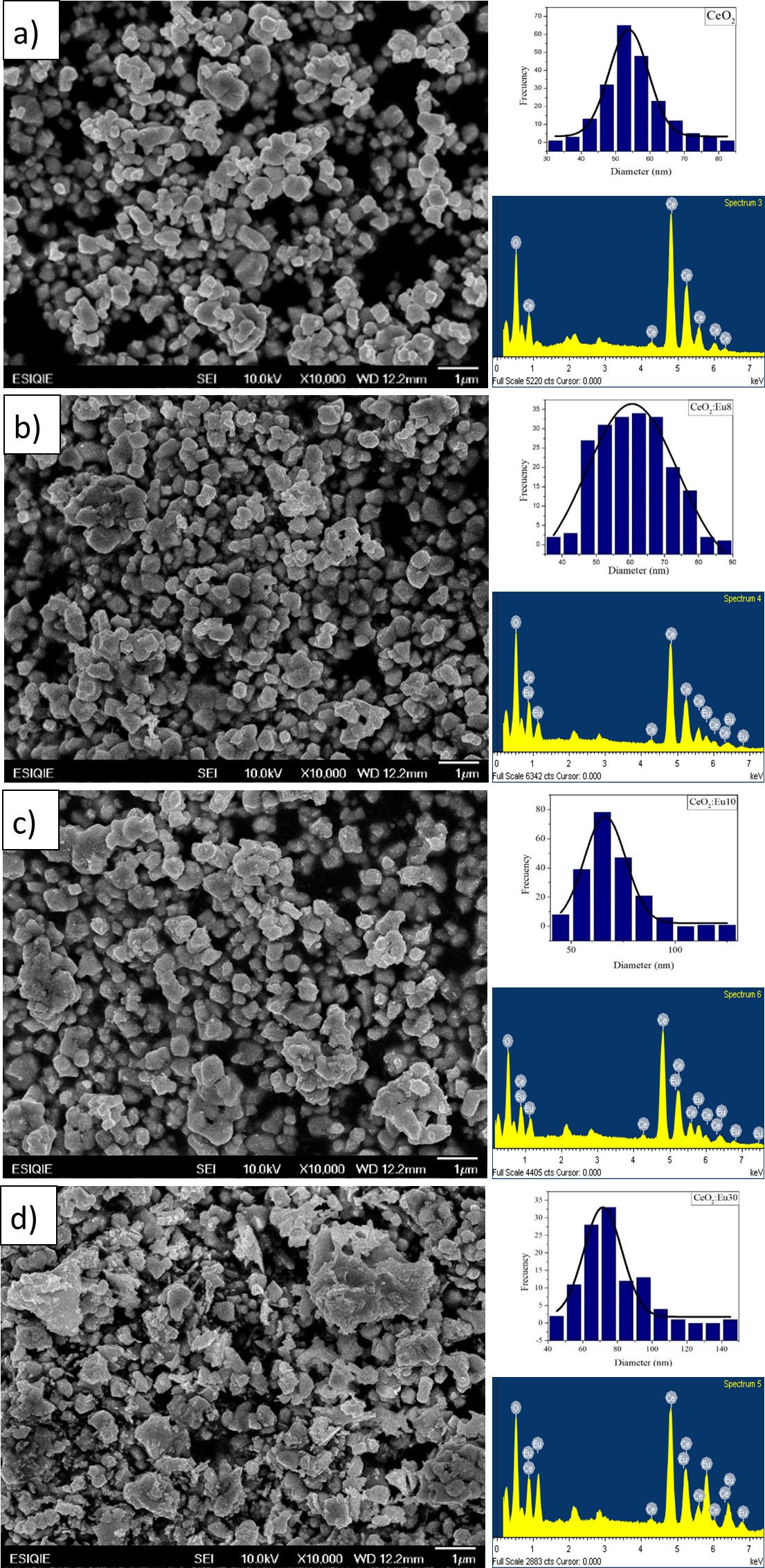

This work aimed to synthesize and characterize CeO2:Eu2O3 ceramic powders with molar concentrations (Ce:Eu = 100:0, 98:2, 95:5, 92:8, 90:10, and 70:30). The gels were heat treated at 700 °C for 24 hours to induce crystallization of the ceramic powders. The materials were characterized by X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), spectroscopy infrared spectroscopy (IR), Raman spectroscopy, scanning electron microscopy (SEM), photoluminescence (PL), and cathodoluminescence (CL). The results reveal that all ceramic powders presented a cubic (fluorite) structure with modifications in the lattice parameters as the Eu3+ concentrations changed. Furthermore, the Eu2O3 diffraction pattern allowed the complete identification of the crystal planes. The crystallite sizes were 64, 22, 30, 38, 40, and 50 nm for the Ce:Eu3+ ceramic powders at 100:0, 98:2, 95:5, 92:8, 90:10, and 70:30, respectively. XPS results showed a Ce3+/Ce4+ ratio of 0.27%. The IR spectrograms show the M-O bands attributable to CeO2 at 460, 560, 860, and 1200 cm-1. The results of the Raman spectra show three main bands at 260, 468, and 600 cm-1, which are associated with the F2g vibration mode of octahedral local symmetry found around the CeO2 lattice and the defect-induced mode related to the presence of oxygen vacancies due to the existence of Ce4+ ions. The particles exhibited morphological changes due to the change from the doped phase to the solid solution. The higher the concentration of Eu3+, the greater its agglomeration and size. The ceramic powders showed luminescent properties exhibiting emissions mainly by the 5D0-7D2 transition of Eu3+ and the 30 mol% sample showed higher luminescent intensity in cathodoluminescence.

References

. A. Singhania, Ind. Eng. Chem. Res. 56, 28 (2017).

https://doi.org/10.1021/acs.iecr.7b03143

. A. Rangaswamy, P. Sudarsanam, B.M. Reddy, J. Rare Earths, 33, 1162 (2015).

https://doi.org/10.1016/S1002-0721(14)60541-X

. S. Gnanam, J. Gajendiran, J.R. Ramya, K. Ramachandran, S.G. Chemical Physics Letters , 763, 138217 (2021).

https://doi.org/10.1016/j.cplett.2020.138217

. Sk. Anirbana, A. Duttaa, Solid State Ionics, 309, 137-145 (2017).

https://doi.org/10.1016/j.ssi.2017.07.020

. T. El-Achari, F. Goumrhar, L.B. Drissi, R.A. Laamara, Physica B: Condensed Matter, 601, 412443 (2021).

https://doi.org/10.1016/j.physb.2020.412443

. T. Zhang, W. Wang, F. Gu, W. Xu, J. Zhang, Z. Li, T. Zhu, G. Xu, Z. Zhong, F. Su, Applied Catalysis B: Environmental, 312, 121385 (2022).

https://doi.org/10.1016/j.apcatb.2022.121385

. T. Senden, A. Meijerink, Journal of Luminescence, 177, 254-260 (2016).

https://doi.org/10.1016/j.jlumin.2016.04.050

. A.D'. Achille, R.M. Wallace, J.L. Coffer, Nanoscale Advances, 12,1212 (2021).

https://doi.org/10.1039/d1na00096a

. F. Carrillo-Romo, A. Alcantar-Mendoza1, A. García-Murillo, M. Díaz-Cruz, Journal of the Australian Ceramic Society, 59, 763–768 (2023).

https://doi.org/10.1007/s41779-023-00872-0

. W. Zhao, J. Rong, W. Luo, L. Long, X. Yao, Applied Surface Science, 579, 152176 (2022).

https://doi.org/10.1016/j.apsusc.2021.152176

. T. Ema, P. Gyu-Choi, S. Takami, Y. Masuda, ACS Appl. Mater. Interfaces, 14, 56998?57007 (2022).

https://doi.org/10.1021/acsami.2c17444

. S. Gao, W. Zhang, H. Zhou, D. Chen, J. Rare Earths, 36, 986-993 (2018).

https://doi.org/10.1016/j.jre.2018.04.002

. A.A. Fakhrabadi, R. Saravanan, M. Jamshidijam, R.V. Mangalaraja, M.A. Gracia, Journal of Saudi Chemical Society, 19, 505-510 (2015).

https://doi.org/10.1016/j.jscs.2015.06.003

. Y. Xu, L. Gao, Z. Ding, Materials, 15, 8971 (2022).

https://doi.org/10.3390/ma15248971

. S. Soni, S. Kumar, B. Dalela, S. Kumar, P.A. Alvi, S. Dalela, Journal of Alloys and Compounds, 752, 520-531 (2018).

https://doi.org/10.1016/j.jallcom.2018.04.157

. J.D. Carregosa, J.P.Grilo, G.S. Godoi, D.A. Macedo, R.M. Nascimento,R.M.P.B. Oliveira, Ceramics International, 46, 23271-23275 (2020).

https://doi.org/10.1016/j.ceramint.2020.06.021

. Z. Yang, Z. Yin, Z. Zhao, J. Yu, J. Li, Z. Ren, G. Yu, Materials Chemistry and Physics, 240, 122148 (2020).

https://doi.org/10.1016/j.matchemphys.2019.122148

. A.P. Anantharaman, J. Geethu, M. Rishab, H. Prasad, J.H. Lee, H. Dasari, G. Babu, Molecular Catalysis, 451, 247-254 (2018).

https://doi.org/10.1016/j.mcat.2018.01.033

.***

. Y. Hernández-Castillo, M. García-Hernández, A. López-Marure, J.H. Luna-Domínguez, P.Y. López-Camacho, Á.J. Morales-Ramírez, Ceramics International, 45, 2303-2308 (2019).

https://doi.org/10.1016/j.ceramint.2018.10.145

. S. Utara, S. Hunpratub, S. Pinitsoontorn, S. Phokha, Results in Physics, 30, 104890, (2021).

https://doi.org/10.1016/j.rinp.2021.104890

. S. Gnanam, V. Rajendran, Journal of Alloys and Compounds, 735, 1854-1862 (2018).

https://doi.org/10.1016/j.jallcom.2017.11.330

. W. Zhao, J. Rong, W. Luo, L. Long, X. Yao, Applied Surface Science, 579, 152176 (2022).

https://doi.org/10.1016/j.apsusc.2021.152176

. R. Mi, D. Li, Z. Hu, R.T. Yang, ACS Catalysis, 11, 7876–7889 (2021).

https://doi.org/10.1021/acscatal.1c01981

. Z. Feng, Q. Ren, R. Peng, S. Mo, M. Zhang, M. Fu, L. Chen, D. Ye, Catalysis Today, 332, 177-182 (2019).

https://doi.org/10.1016/j.cattod.2018.06.039

. Z. Su, W. Yang, C. Wang, S. Xiong, X. Cao, Y. Peng, W. Si, Y. Weng, M. Xue, J. Li, Treatment and Resource Recovery, 54, 12684–12692 (2020).

https://doi.org/10.1021/acs.est.0c03981

. P. Wang, J. Wang, J. Shi, X. Du, X. Hao, B. Tang, A. Abudula, G. Guan, Molecular Catalysis, 492, 111027 (2020).

https://doi.org/10.1016/j.mcat.2020.111027

. M. Wang, N. Shang, W. Gao, X. Cheng, S. Gao, C. Wang, Fuel, 354, 129433 (2023).

https://doi.org/10.1016/j.fuel.2023.129433

. E. Cerrato, E. Gaggero, P. Calza, M.C. Paganini, Chemical Engineering Journal Advances, 10, 100268 (2022).

https://doi.org/10.1016/j.ceja.2022.100268

. P. Min, S. Zhang, Y. Xu, R. Li, Applied Surface Science, 448, 435-443 (2018).

https://doi.org/10.1016/j.apsusc.2018.04.103

. M.L. Camacho-Ríos, R. A. Ochoa-Gamboa, W. Antunez, D. Lardizabal, Microscopy and Microanalysis, 25, 1792-1793, (2019).

https://doi.org/10.1017/S1431927619009693

. S. Milad, A. Nsar, Z. Hassan, K.Y. Cheong, W.F. Lim, W.F. Lim, Journal of Materials Science: Materials in Electronics, 34, 810 (2022).

https://doi.org/10.1007/s10854-023-10172-9

. L. Li, H.K. Yang, B.K. Moon, Z. Fu, C. Guo, J.H. Jeong, S.S. Yi, K. Jang, H.S. Lee, J. Phys. Chem., 113, 610–617 (2009).

https://doi.org/10.1021/jp808688w

. C. Li, Q. Xiao, Y. Fu, Y. Liang, C. Liu, Y. Zhuang, L. Xia, Journal of Non-Crystalline Solids, 552, 120453 (2021).

https://doi.org/10.1016/j.jnoncrysol.2020.120453

. L. HE, Y. SU, J. Lanhong, S. SHI, Journal of Rare Earths, 33, 791-799 (2015).

Downloads

Published

Issue

Section

License

Copyright (c) 2025 The authors; licensee SMCTSM, Mexico.

This work is licensed under a Creative Commons Attribution 4.0 International License.

©2026 by the authors; licensee SMCTSM, Mexico. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).