Optical and structural properties of Fe2O3-ZnO composite thick films obtained by ultrasonic spray pyrolysis

DOI:

https://doi.org/10.47566/2023_syv36_1-231101Keywords:

Fe2O3-ZnO composite, Ultrasonic Spray Pyrolysis, Band gap ModulationAbstract

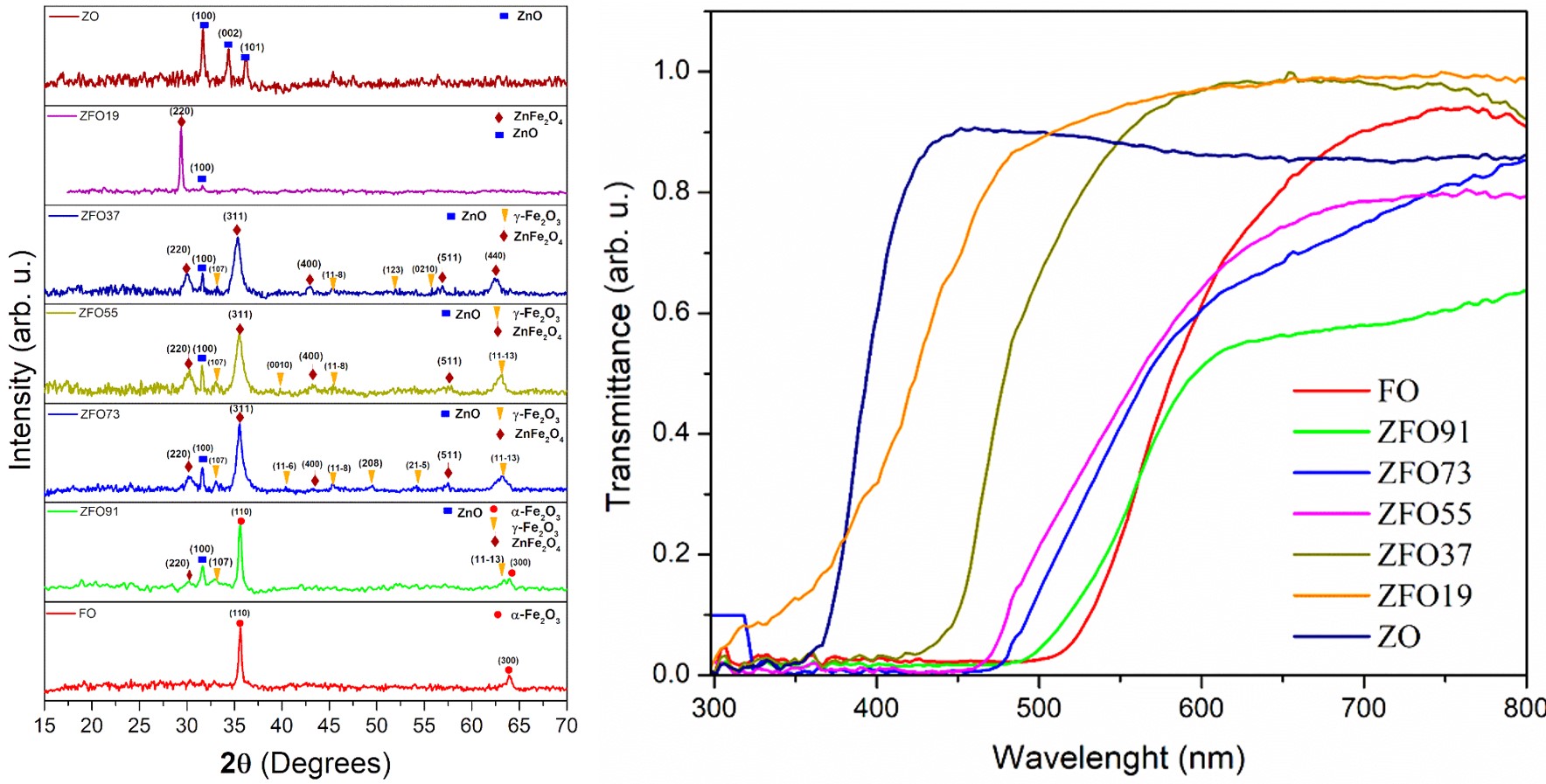

Fe2O3-ZnO composite gained attention due the several applications like that sensors, photocatalysis, reduction of mercury ions. Fe2O3-ZnO composite thick films were prepared by Ultrasonic Spray Pyrolysis on a glass substrate, using 0.1 M aqueous solutions of FeCl3?6H2O and ZnCl2 anhydride. To obtain different elemental concentration of Fe and Zn, we varied the volume of each aqueous solution. The XPS analysis shown that it is possible to modulate the concentration of Zn and Fe in the samples. The X-ray diffraction measurements revealed that the films were composed of different phases corresponding with common stable iron oxides (ZnFe2O4, Fe2O3) and zinc oxide (ZnO). Results from Raman spectroscopy indicate that Fe2O3 vibrational modes are accompanied with new modes due to the presence of additional phases ZnO compounds. The band gaps were evaluated with the help of UV-visible transmittance data using the Tauc model, the results shown a modulation of the band gap values (2.2 eV to 3.2 eV). Theorical transmittance curves were obtained using the effective medium theory, using the Bruggeman model, these curves showed similar behavior that the experimental transmittance curves.

References

. S.H. Güler, Ö. Güler, E. Evin, S. Islak, Optik 127, 3187 (2016).

https://doi.org/10.1016/j.ijleo.2015.12.103

. H. Lachheb, F. Ajala, A. Hamrouni, A. Houas, F. Parrino, L. Palmisano, Catal. Sci. Technol. 7, 4041 (2017).

https://doi.org/10.1039/c7cy01085k

. R.D. Suryavanshi, K.Y. Rajpure, J. Photochem. Photobiol. A Chem. 357, 72 (2018).

https://doi.org/10.1016/j.jphotochem.2018.02.008

. J.K. Nayak, P. Roy Chaudhuri, S. Ratha, M.R. Sahoo, J. Electromagn. Waves Appl. 37, 282 (2023).

https://doi.org/10.1080/09205071.2022.2135029

. J. Sancho-Parramon, V. Janicki, J. Phys. D. Appl. Phys. 41, 215304 (2008).

https://doi.org/10.1088/0022-3727/41/21/215304

. J.Y. Lu, A. Raza, N.X. Fang, G. Chen, T. Zhang, J. Appl. Phys. 120, 163103 (2016).

https://doi.org/10.1063/1.4966119

. R.N. Abed, M. Kadhom, D.S. Ahmed, A. Hadawey, E.Yousif, Trans. Electr. Electron. Mater. 22, 317 (2021).

https://doi.org/10.1007/s42341-020-00242-8

. A. Heilmann, G. Kampfrath, V. Hopfe, J. Phys. D. Appl. Phys. 21, 986 (1988).

https://doi.org/10.1088/0022-3727/21/6/020

. C.F. Baes. R.F. Mesmer, Am. J. Sci. 281, 935 (1981). https://doi.org/ 10.2475/ajs.281.7.935

. B. Beverskog, I. Puigdomenech, Corros. Sci. 39, 107 (1997).

https://doi.org/10.1016/S0010-938X(97)89246-3

. A.K. Baev, E.A. Evsei, Russ. J. Inorg. Chem. 55, 508 (2010).

https://doi.org/10.1134/S0036023610040054

. W. Kiefer, J. Raman Spectrosc. 38, 1538 (2007).

https://doi.org/10.1002/jrs.1902

. V. D’Ippolito, G.B. Andreozzi, D. Bersani, P.P. Lottici, J. Raman Spectrosc. 46, 1255 (2015)

https://doi.org/10.1002/jrs.4764

. S. Choudhary, A. Bisht, S. Mohapatra, Ceram. Int. 47, 3833 (2021).

https://doi.org/10.1016/j.ceramint.2020.09.243

. X. Li, B. Jin, J. Huang, Q. Zhang, R. Peng, S. Chu, Solid State Sci. 80, 6 (2018).

https://doi.org/10.1016/j.solidstatesciences.2018.03.016

. J. Bai, Mater. Lett. 63, 1485 (2009).

https://doi.org/10.1016/j.matlet.2009.03.052

. R.M. Mohamed, A.A. Ismail, Sep. Purif. Technol. 266, 118360 (2021).

Downloads

Published

Issue

Section

License

Copyright (c) 2023 The authors; licensee SMCTSM, Mexico.

This work is licensed under a Creative Commons Attribution 4.0 International License.

©2026 by the authors; licensee SMCTSM, Mexico. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).